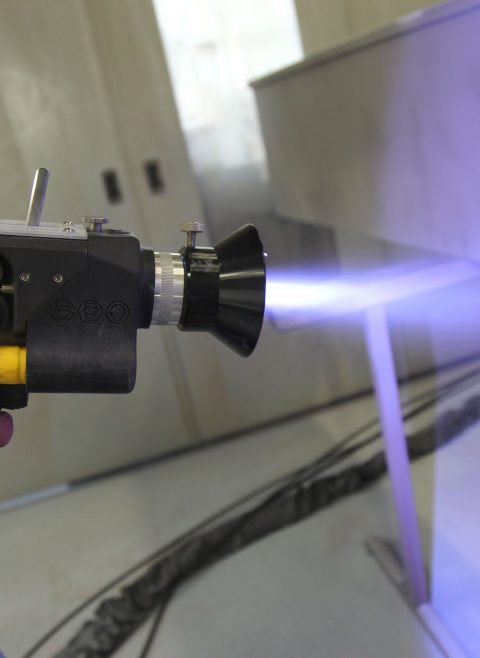

Thermal Arc Metal Spraying

To complement our powder coating services, we can also offer thermal arc metal spraying.

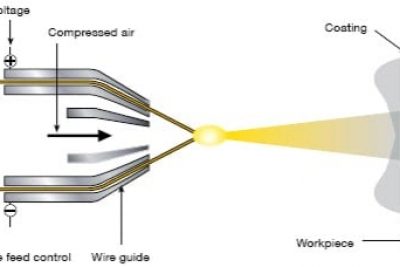

Thermal metal spray is a process where metal wire is passed through an electric arc to melt it, and then sprayed onto a prepared surface by the use of compressed air, to form a continuous layer. Unlike hot dip galvanizing, there is very little heat build up, and distortion is all but eliminated. There is no real limit to the thickness of sprayed coatings, zinc may be sprayed to over 3mm and unlike galvanising, thicknesses may be varied from place to place to provide different protection levels for different areas. Sealed tubular or hollow sections can be coated externally without the need for venting, thus eliminating the danger of explosion.

Metal spraying is a very flexible process. The range or materials that can be sprayed is almost limitless. Basically, if a material can be heated to its melting point without boiling away, the material can be sprayed. It is not only zinc that can be sprayed, other common materials such as copper, stainless steel, aluminium, bronze and phosphor bronze can also be used.